TARFORM

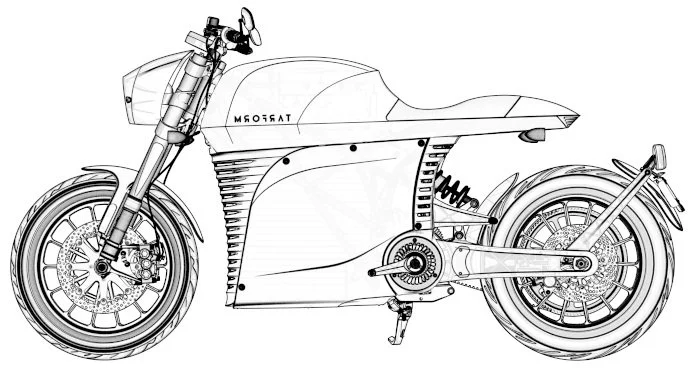

Tarform Motorcycles is an automotive startup with a mission to set a new standard for two wheeled transportation. Launching a new breed of electric motorcycles by integrating cutting edge technology, green mobility and smart connectivity.

Credits. Drew Gurian

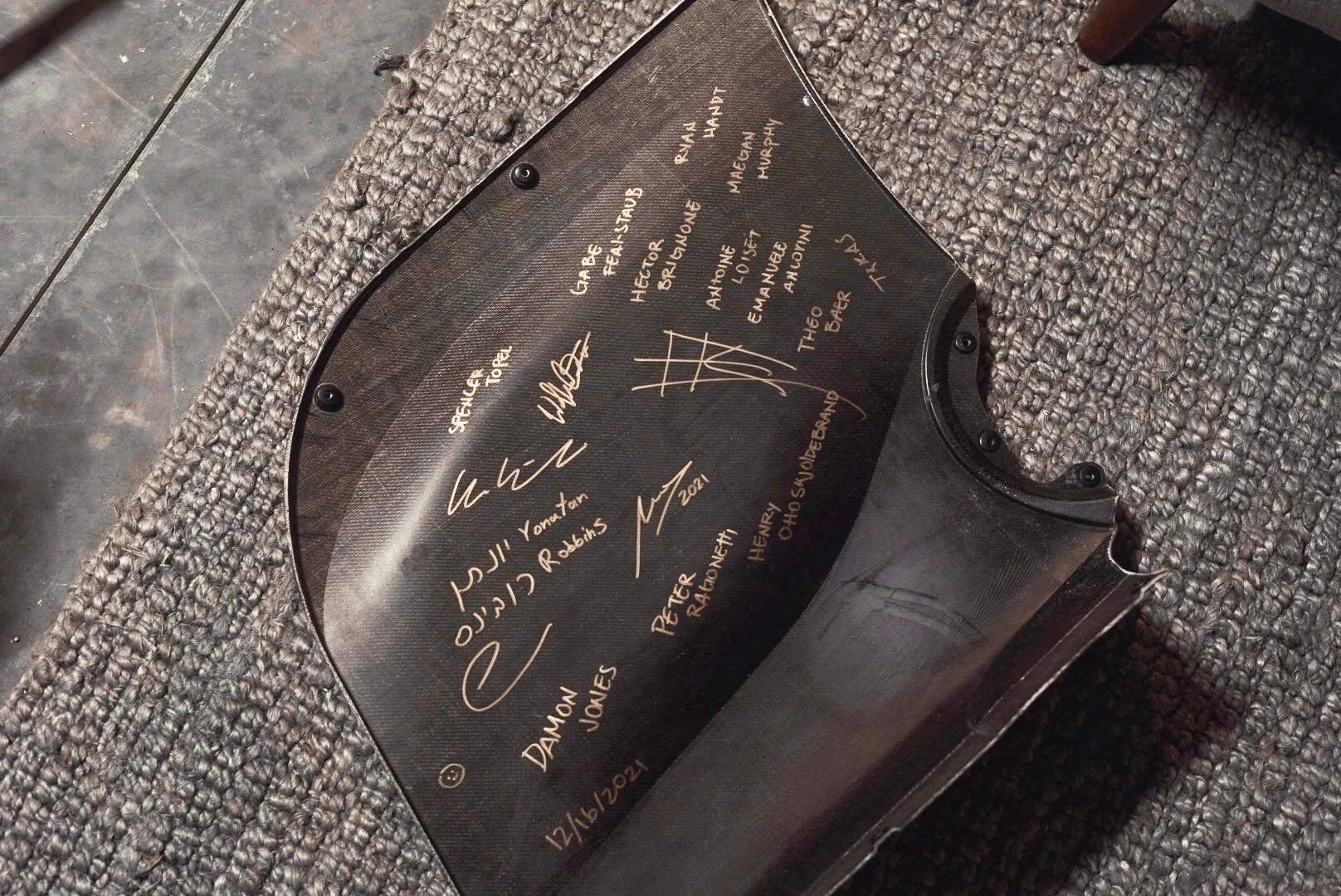

Team. T.Kravtchouk, D.Jones, P.Ragonetti, C.Barbe, Y.Robbins, G.Feal-Staub, E.Bear, S.Topel, A.Loiselet, H.Otto, JC.Jung, J.Goldner and more talented individuals

Marlon joined this group of entrepreneurs, designers, engineers and biologists with an affinity and drive for combining innovation and function.

Credits. Tarform

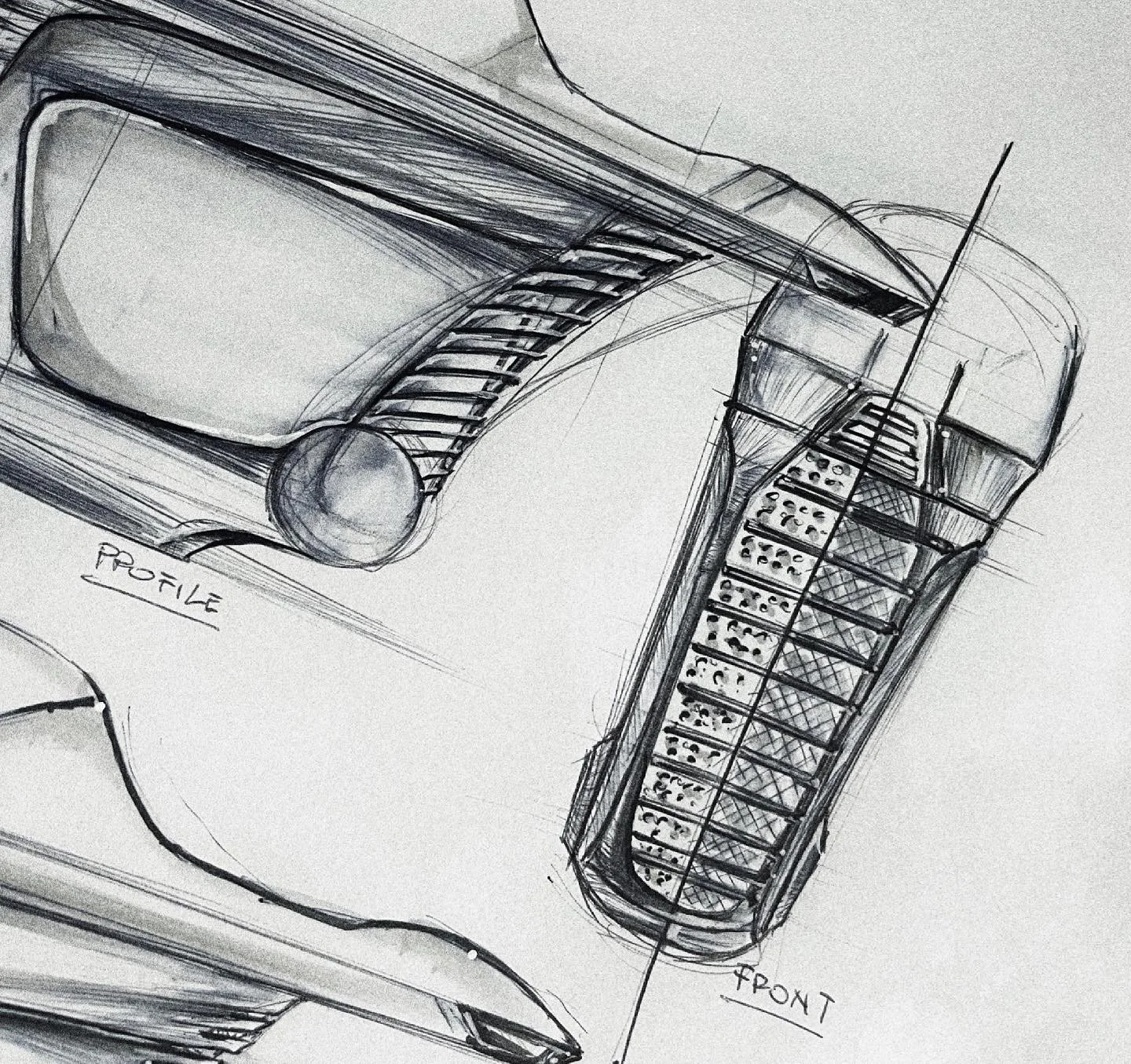

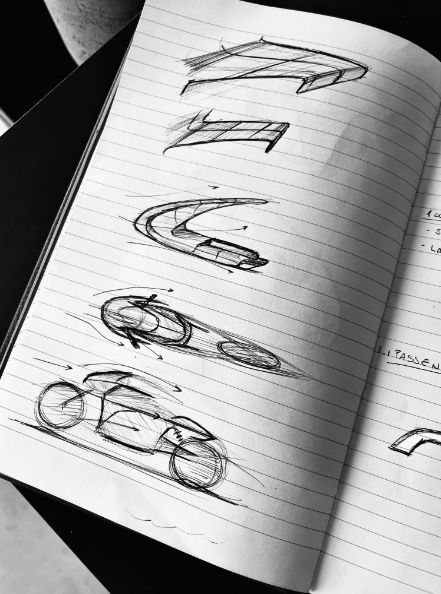

CONCEPT

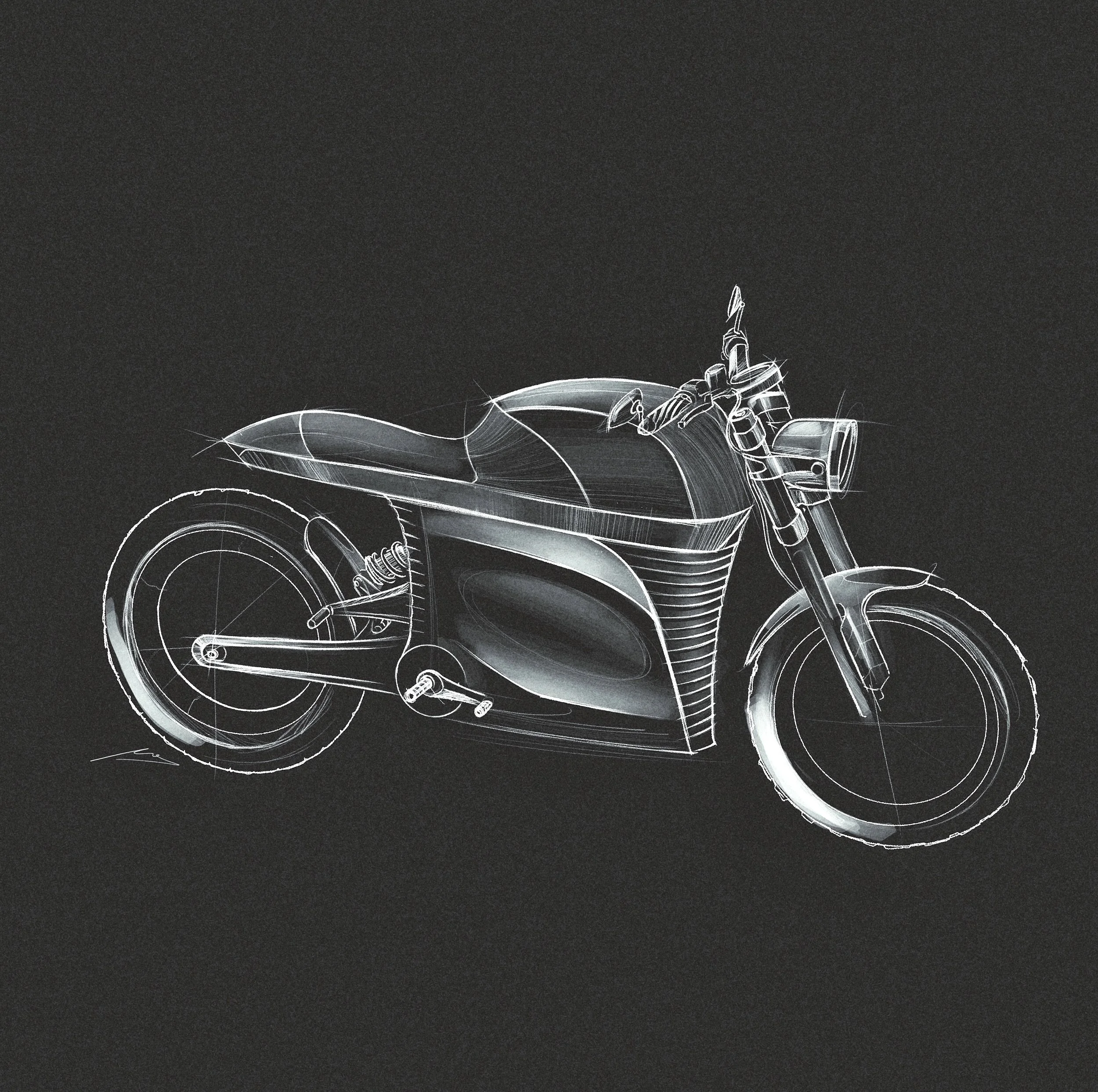

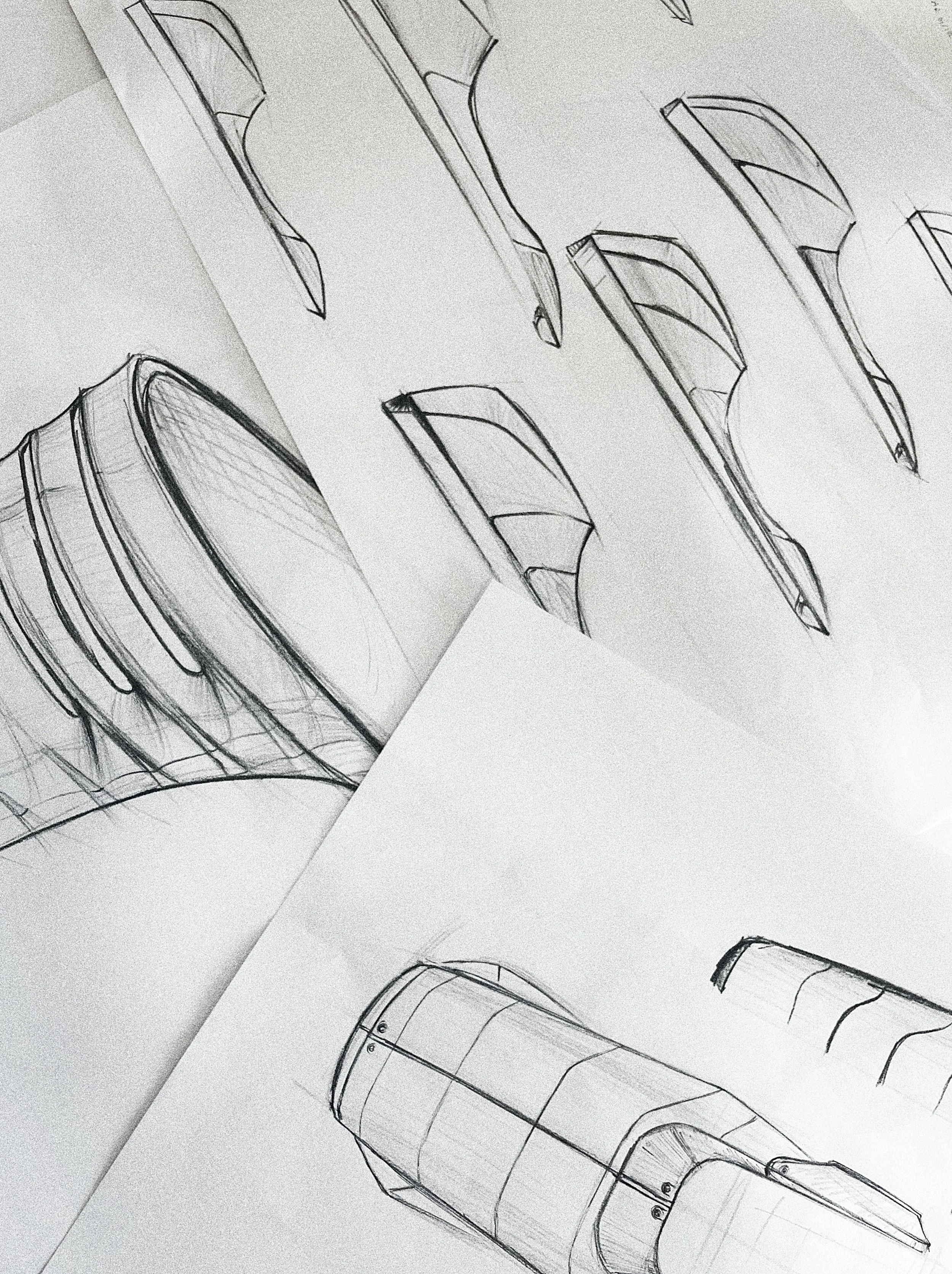

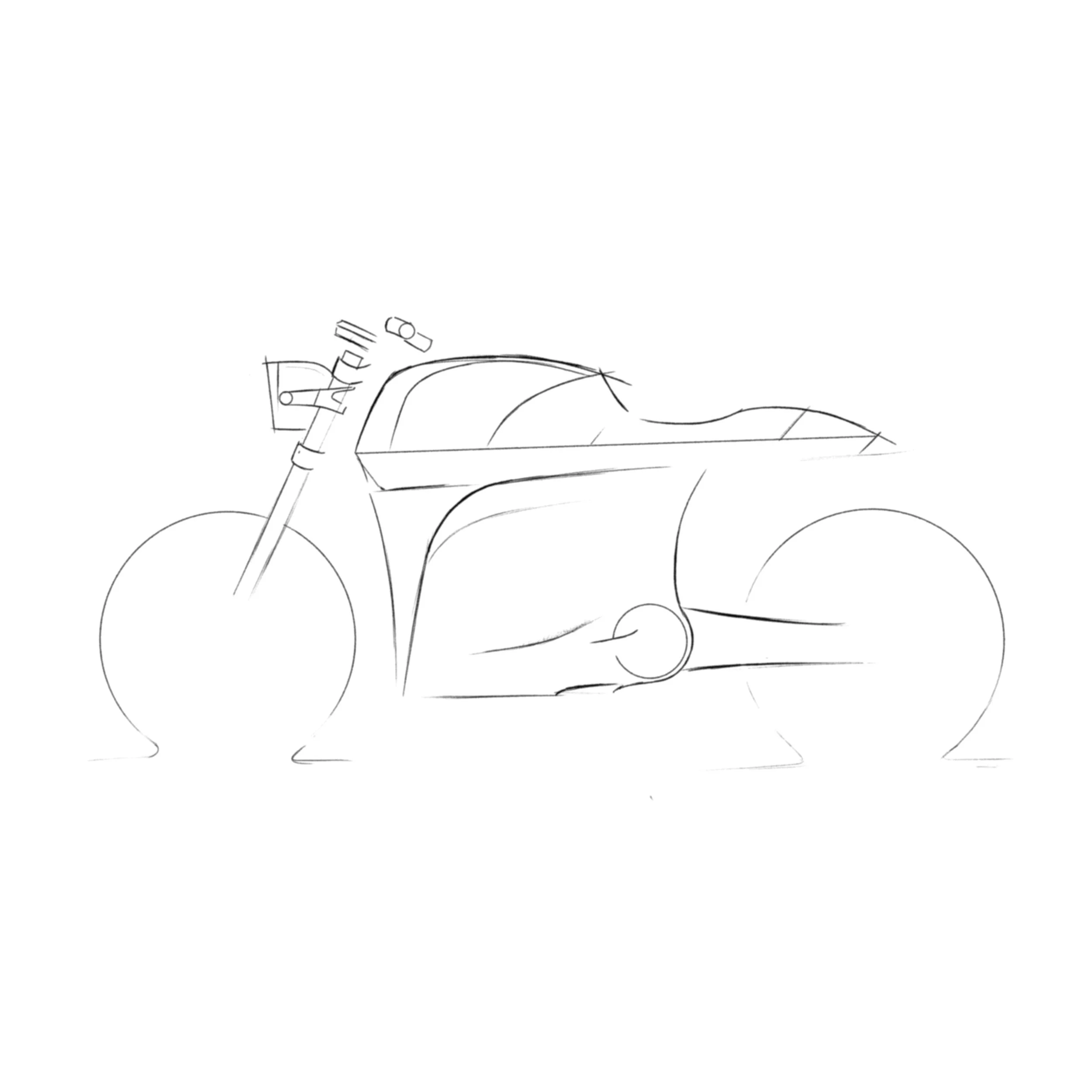

Tarform's design team was given the assignment of transitioning to a more organic aesthetic. This was Marlon’s proposal, which later served as the basis for the Founder's Edition models.

(Said first lines were polished by Tarform’s Head designer T.Kravtchouk)

Beauty is a powerful tool in the fight for sustainability as it encourages individuals to cherish and repair their possessions, rather than disposing of them due to obsolescence. By prioritizing aesthetically pleasing and durable design, we can reduce waste and promote a more sustainable approach to consumption.

*Skills: Sketching Rendering 3D modeling Organizational skills Creativiy / Collaboration / Communication

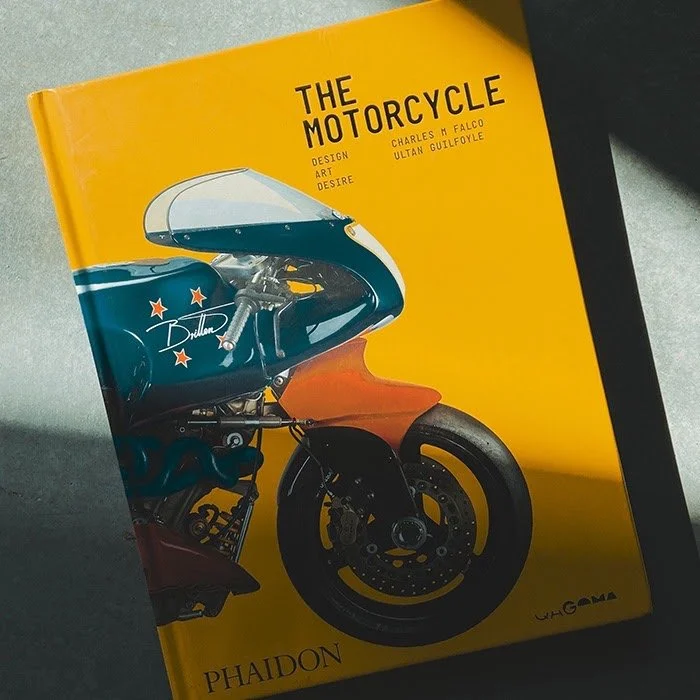

Marlon was able to find the ideal proportions for the bike and placed the initial sketch model in QAGOMA

Tarform 2019

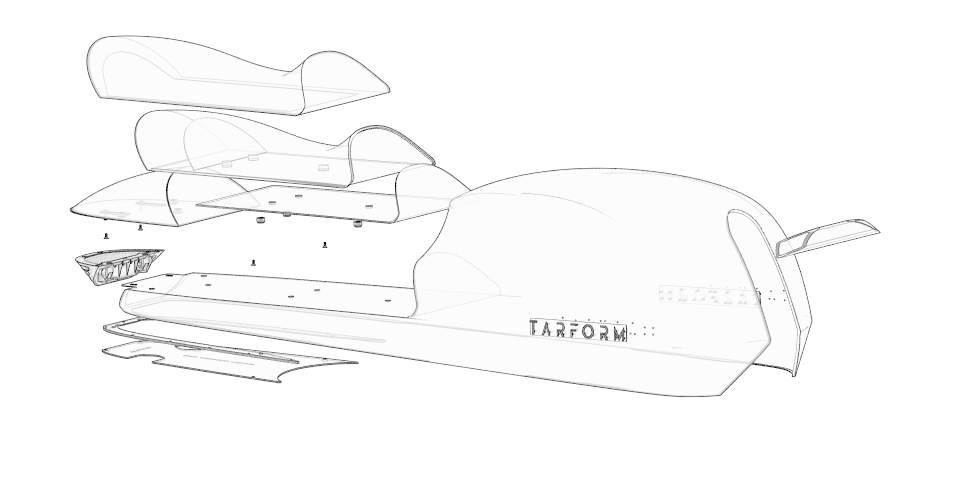

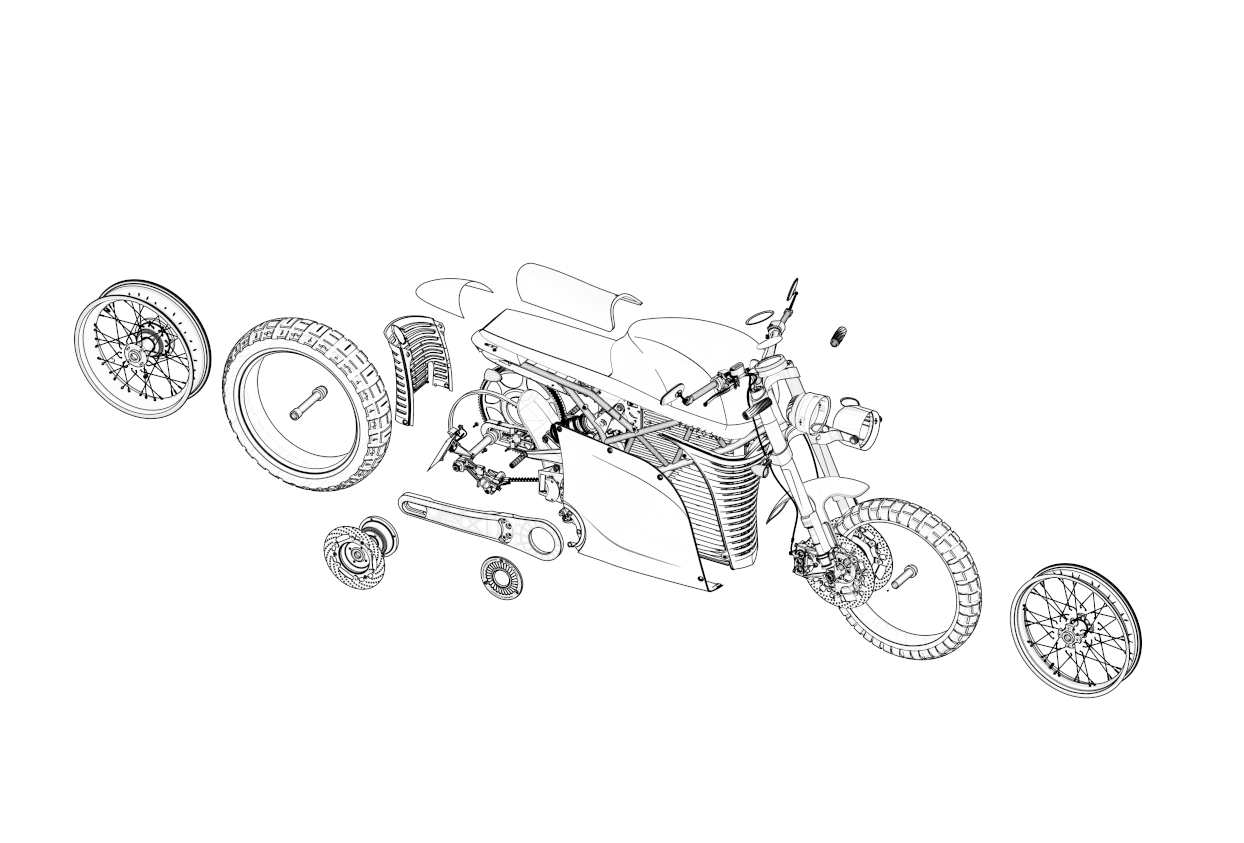

Tarform has designed a modular platform for the motorcycle, prioritizing a system solution over a one-life product. This allows upgrading chassis items such as technological advances and trends evolve, providing a flexible and adaptable solution. The company's focus on future-proof and sustainable design ensures that the platform stays at the forefront of innovation in the industry.

The public and prestigious publications, ranging from National Geographic to Top Gear, have taken notice of Tarforms' entrepreneurial and innovative design approach.

Credits. QAGOMA

Credits. DisneyPlus The world according to Jeff Goldblum Season 2 Ep.8

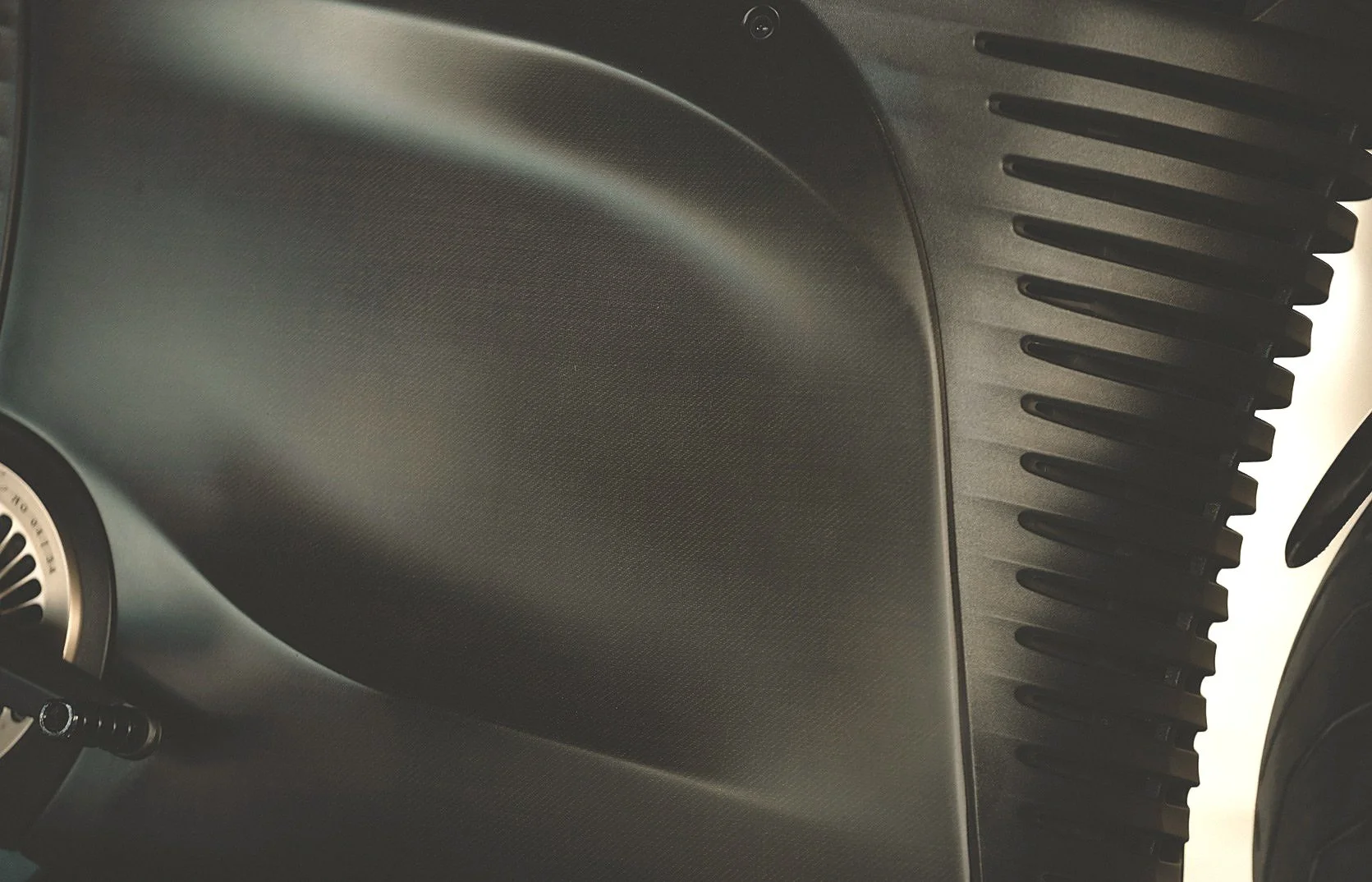

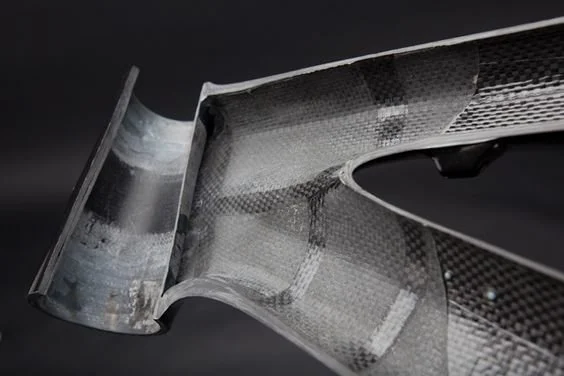

COMPOSITES

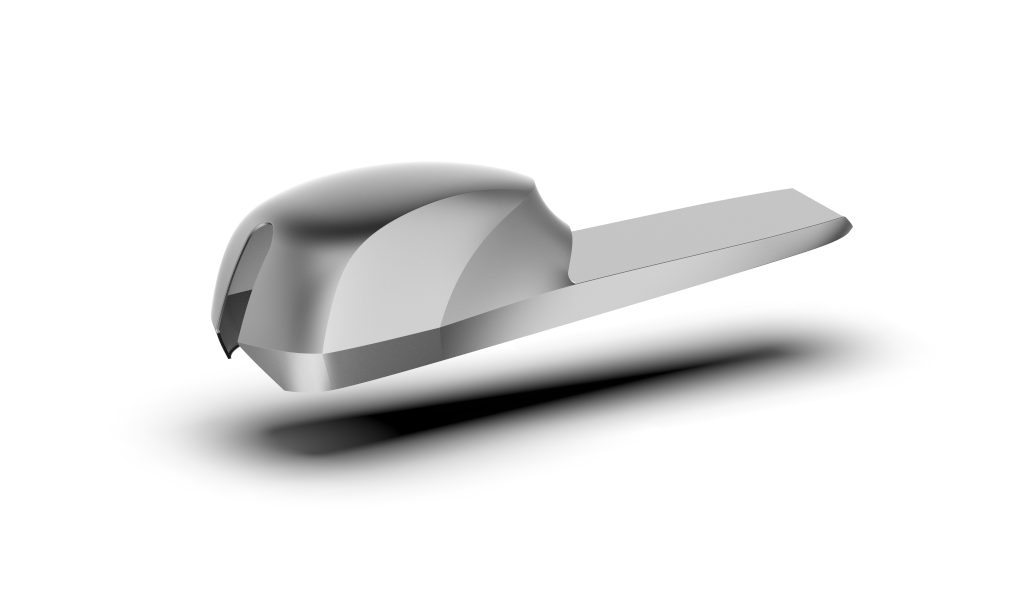

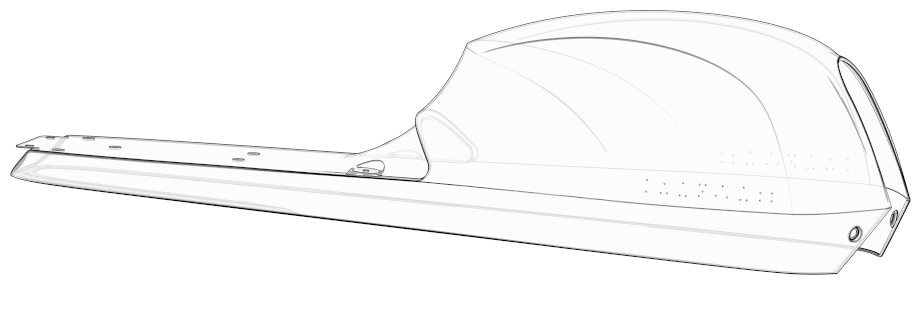

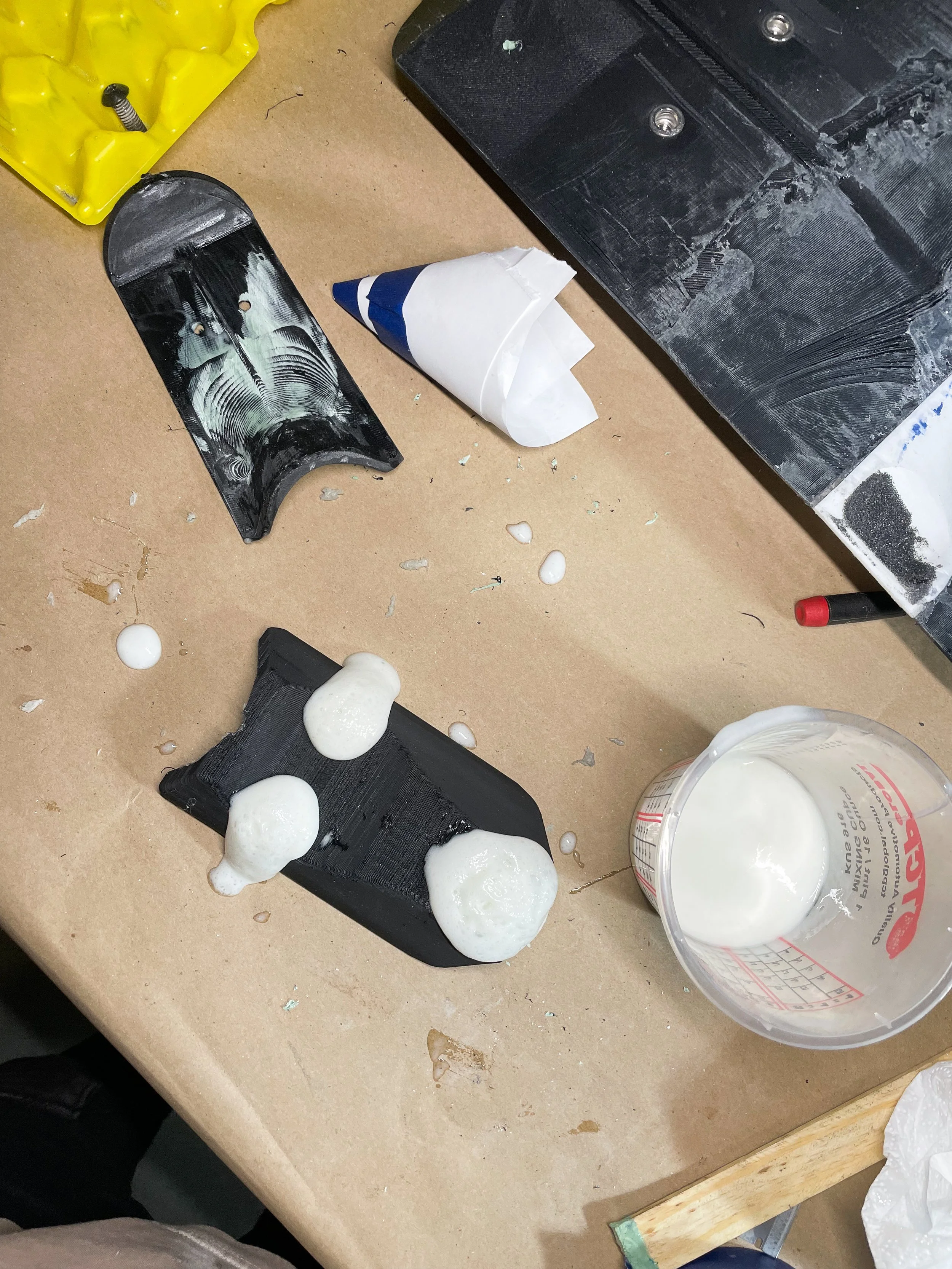

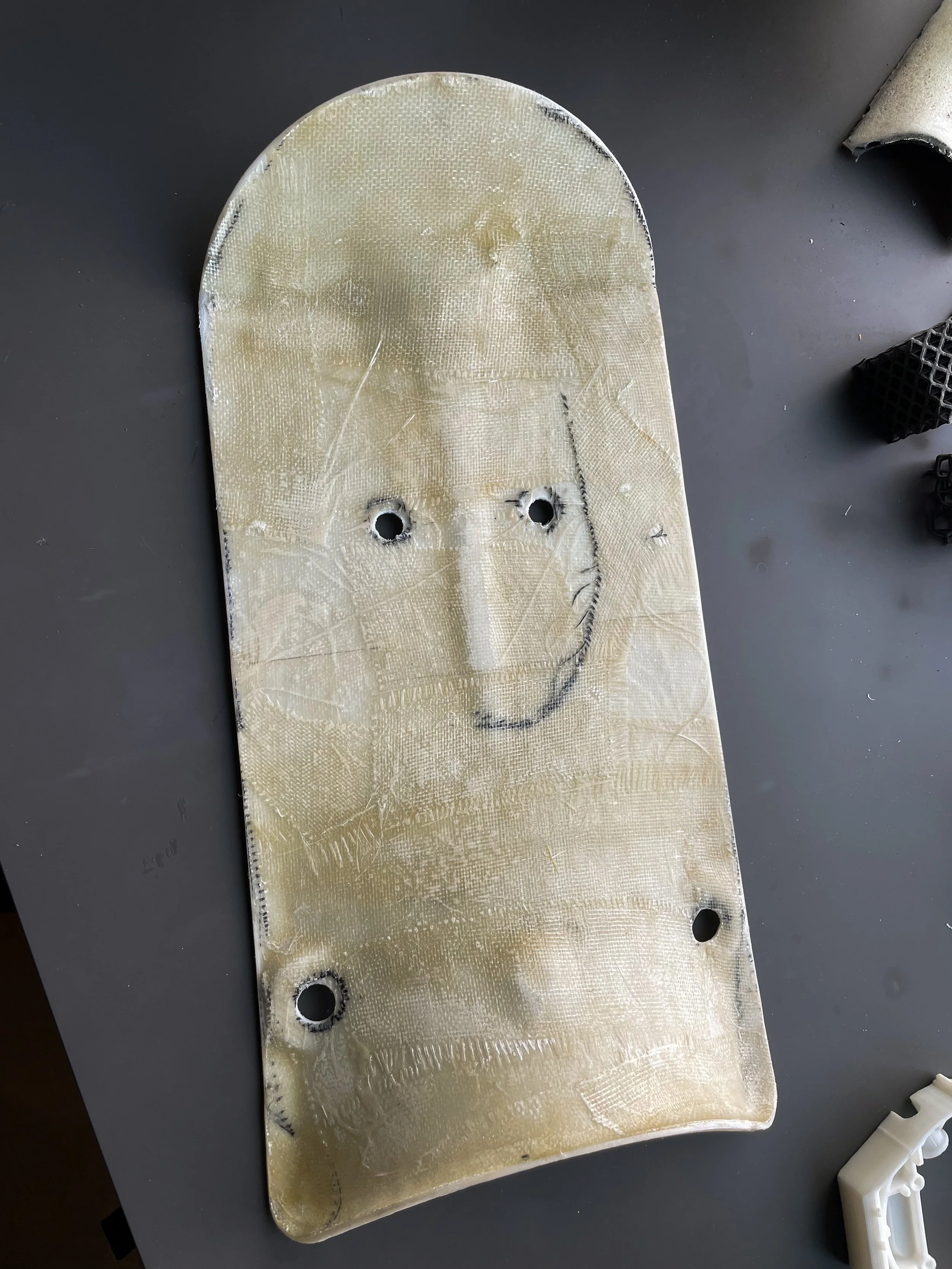

Marlon guided the visual direction of the project, including the creation of the mold required for production of the proprietary composite package used in the first bikes produced by Tarform.

Motorcyle side panel signed by team members

Female mold

Male mold

The design is easily replaceable, allowing for updates as trends evolve.

*Skills: Surface A modeling Leadership Prototyping VRM Creativiy / Collaboration / Critical thinking

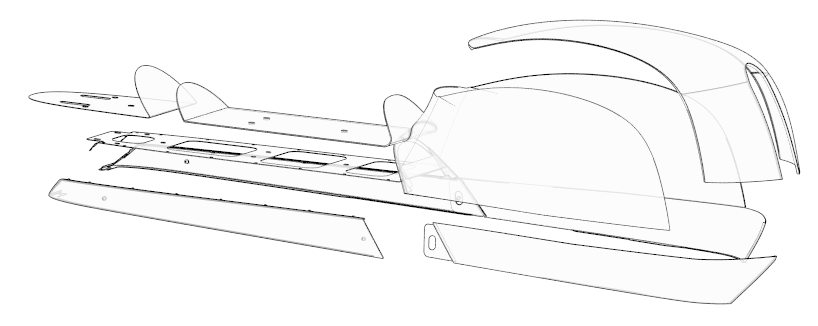

In order to transition to mass production of high-quality tanks, the development of composite body work was pursued as an alternative to the artisanal aluminum tanks used on the motorcycles previously.

Aluminium

Flax

*Skills: Surface A modeling Leadership Prototyping Engineering CNC Creativiy / Collaboration / Critical thinking

Wood buck

Monocoque V2

Hybrid v2

Monocoque V4

Casting V2

Casting V4

The optimal solution would incorporate Tarform's biobased composites into the manufacturing process, allowing for a more sustainable approach. In order to achieve cost efficiency and reliability, every aspect of the manufacturing was redesigned.

mech + Design

The seamless collaboration and synchronization between mechanical engineering, design, and material science are key to creating a vehicle that can redefine the future of mobility. The key to maintaining this balance lies in having a team that is capable of effectively working together to solve problems.

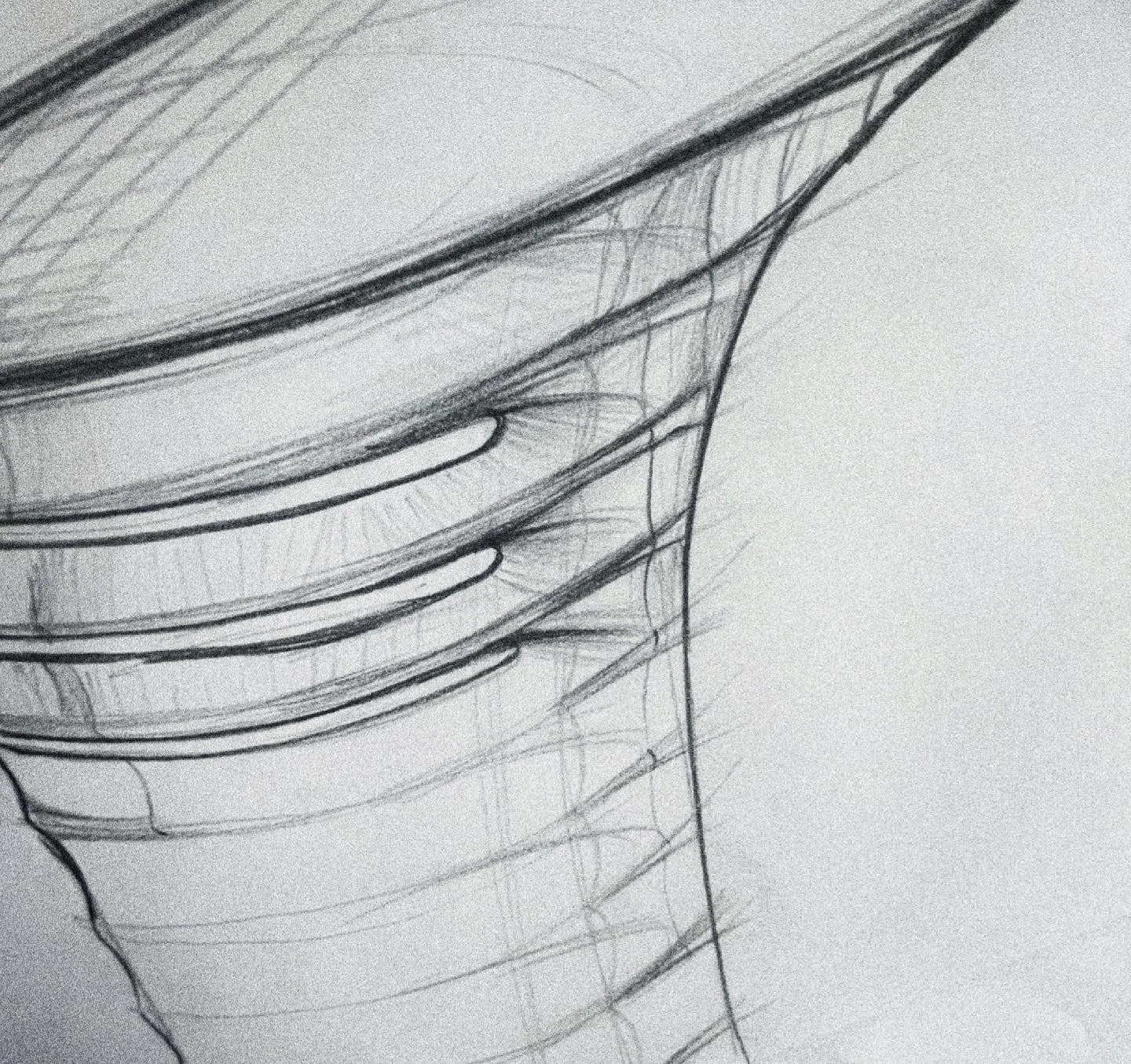

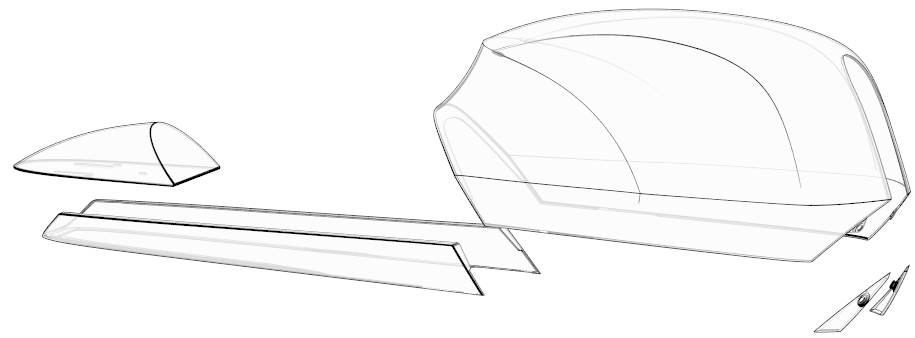

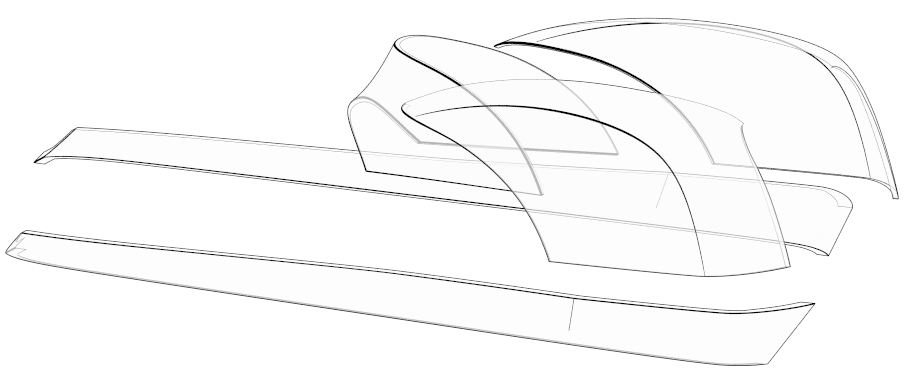

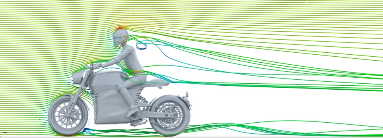

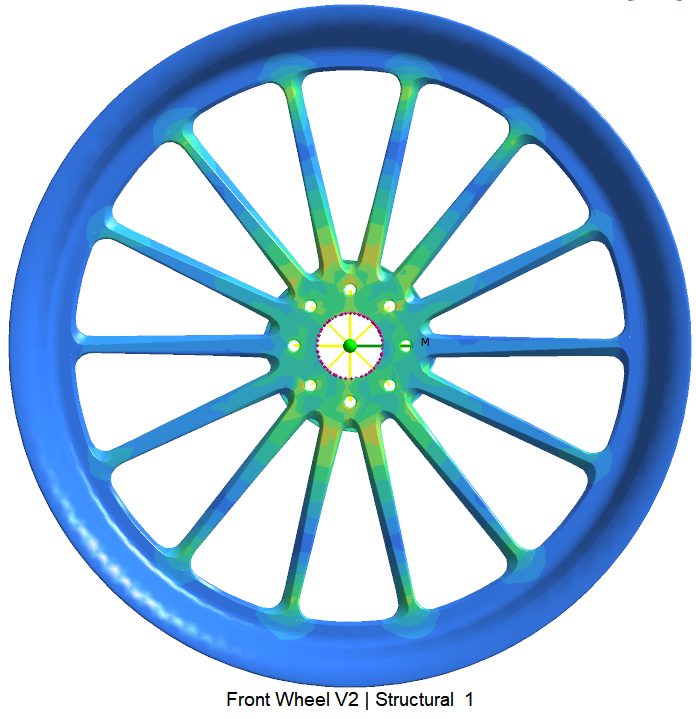

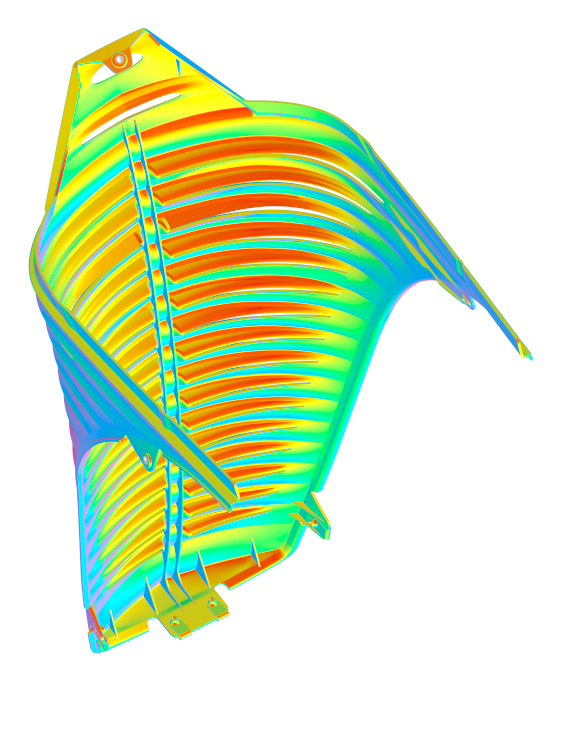

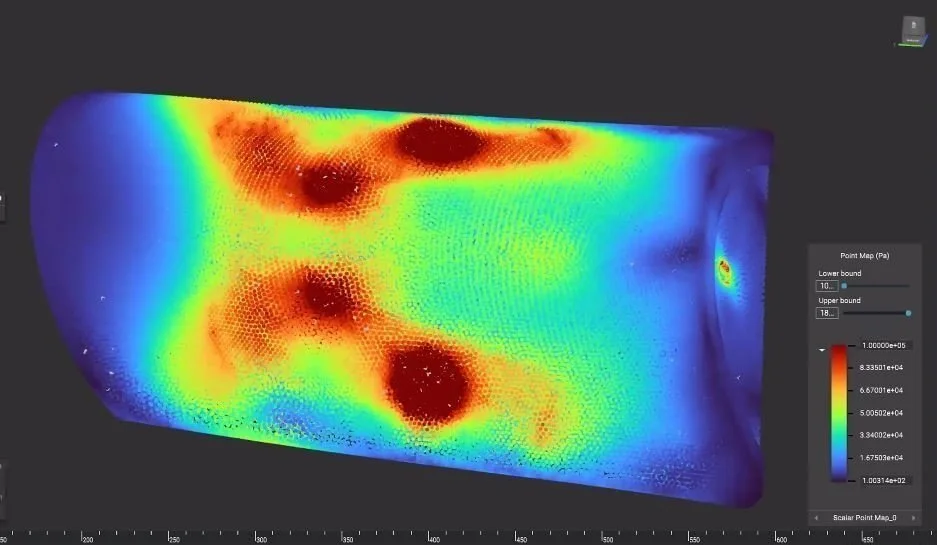

Optimizing the aerodynamics is crucial to achieve the maximum range for an EV. By designing a vehicle with superior aerodynamic properties, the air resistance is reduced, and the energy required to move the vehicle is minimized, resulting in an increased range. The rider's position poses the biggest challenge for aerodynamics in motorcycle design.

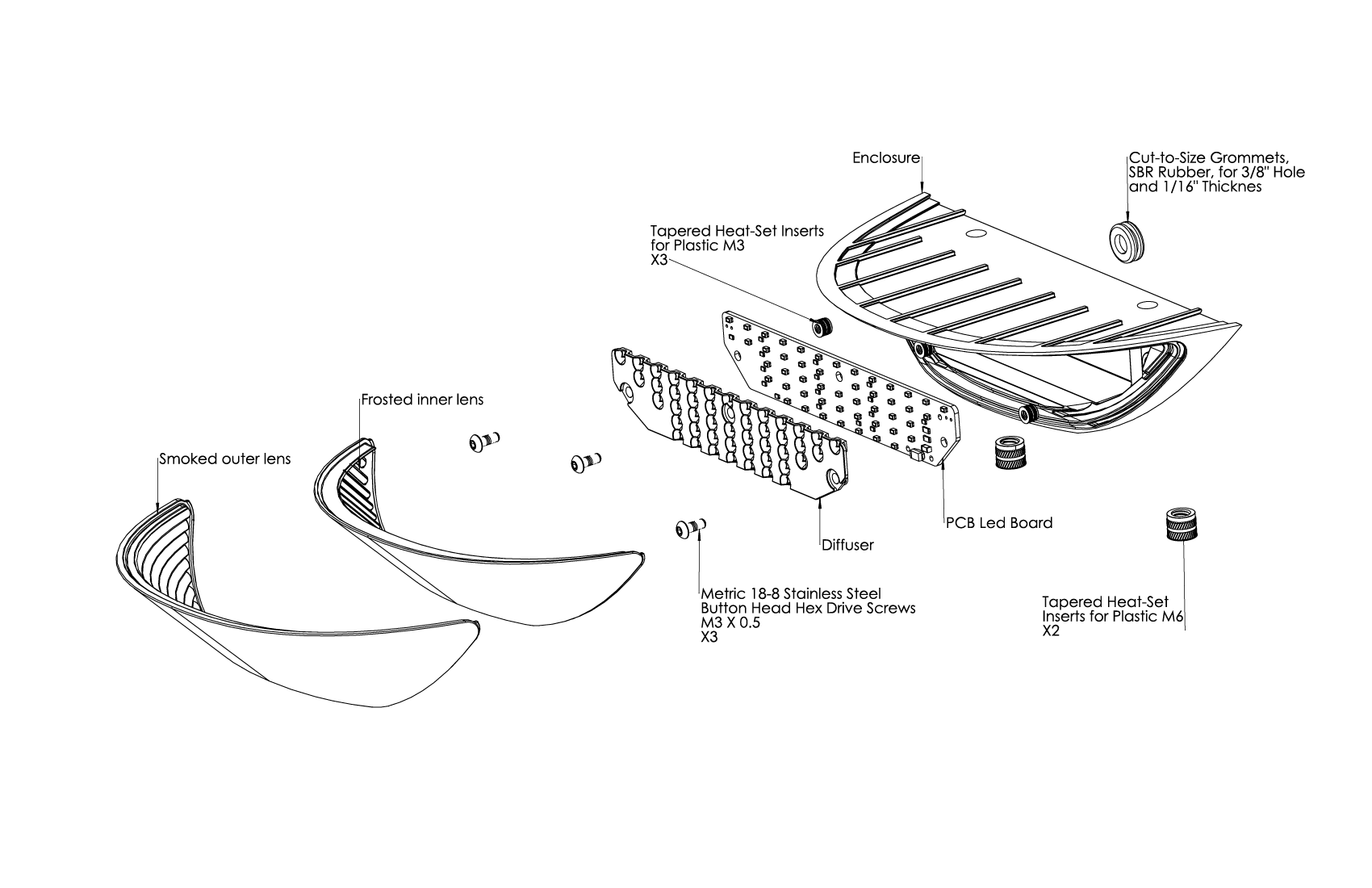

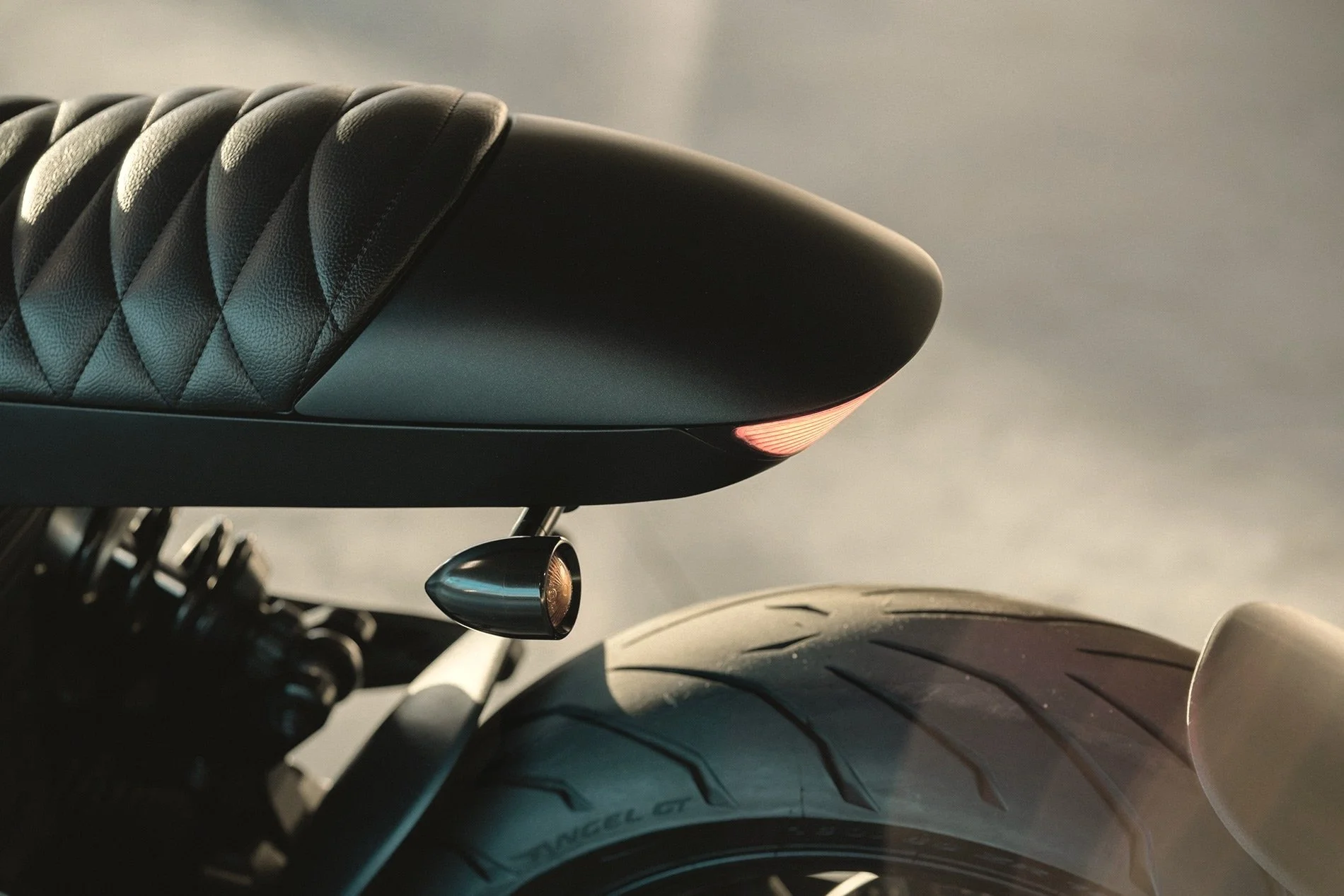

Marlon played a crucial role in developing and achieving the desired light diffusion while ensuring the automotive assembly was mechanically sound and waterproof.

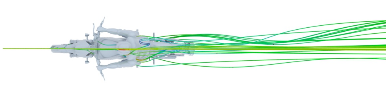

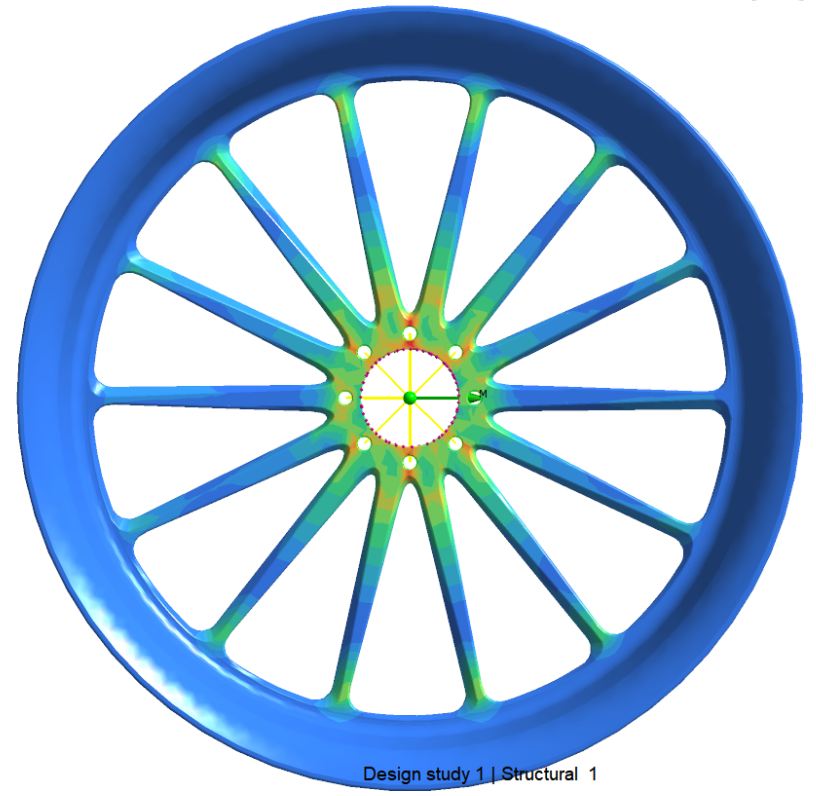

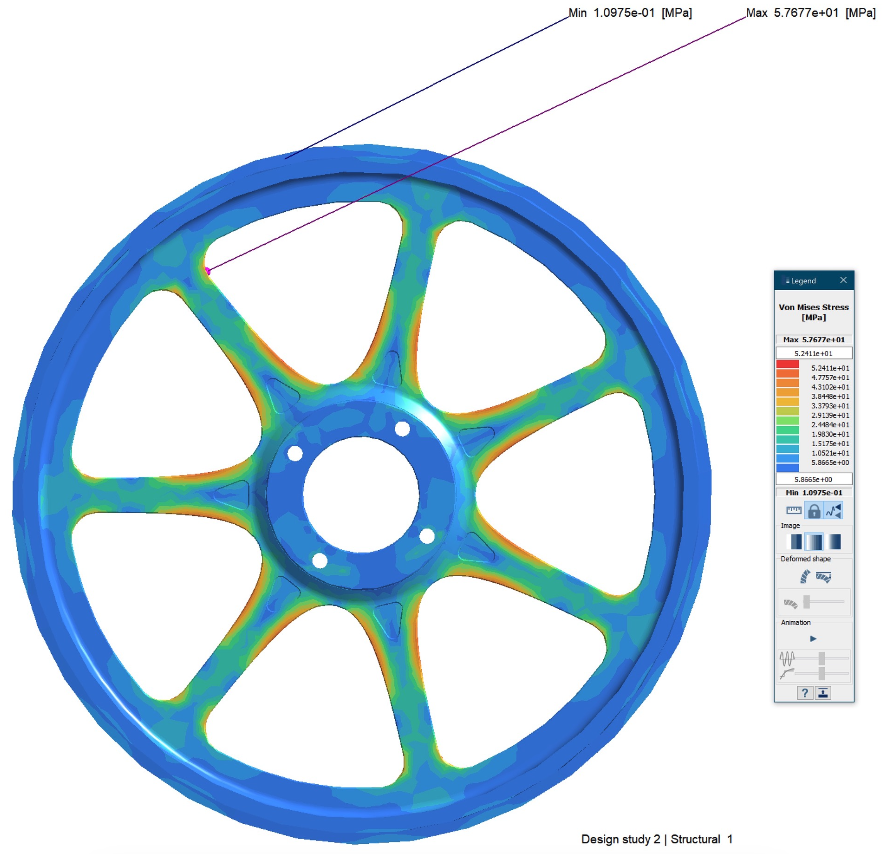

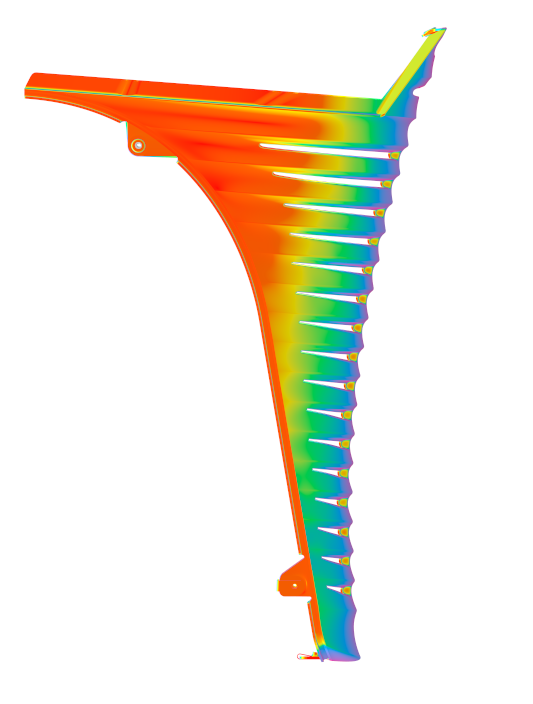

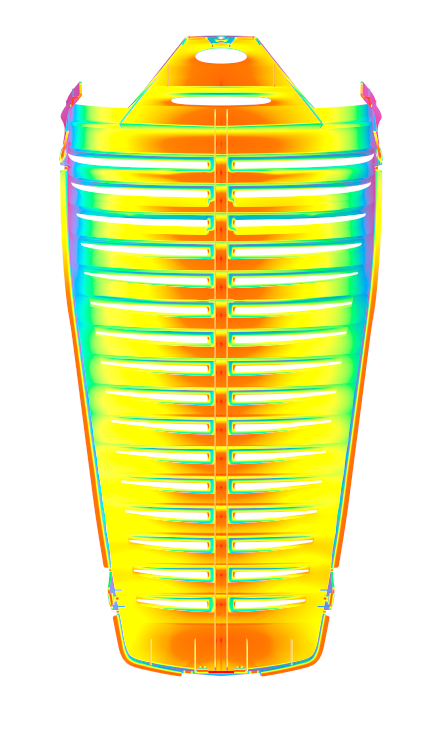

In the event of an FEA failure, re-iteration is necessary to ensure the vehicle's structural integrity.

*Skills: Sketching Rendering 3D modeling Organizational skills User Research Material knowledge Communication / Collaboration / Critical thinking

Developing safe geometries for vehicles is critical, and design iterations play a crucial role in achieving this. Through multiple studies of finite element analysis cases, performance, safety, and design are optimized.

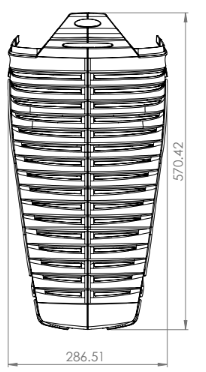

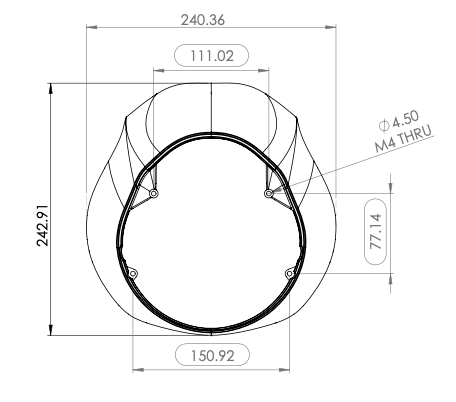

CASTING

3D printing was a valuable tool for exploring the creation of the first bikes. However, as delivery volumes increased, there was a need for a more cost-efficient and sustainable system. Although injection molding is not the best option for customized quantities, the components were designed with injection molding standars that can improve the molding process for future production needs, aiming to reduce costs and minimize environmental impact.

*Skills: Surface A modeling Prototyping Research Engineering 3D print Communication / Collaboration / Critical thinking

MATERIALS

To offer an alternative to traditional vinyl or leather seat options, a new type of leather had to be introduced that met automotive standards for exterior use that is resistant to weather and abrasion. Despite the challenges involved, numerous materials were explored, including plant-based, upcycled, and even shrimp-based leather. Ultimately, with the help of suppliers and the relationships built during the research process, the best bio leather was chosen for the automotive application in need, meeting the necessary standards for exterior use.

Marlon played an important role in ensuring that the sustainable materials incorporated in the Tarform motorcycle not only met industry standards but also have the necessary physical properties for high-quality design. He prioritized the quality and functionality of the materials, and his leadership led to extensive research and knowledge acquisition on selecting the best materials with these properties. Through managing manufacturer relationships and research outsourcing, the Tarform founder edition motorbike offers a product line with a diverse range of sustainable materials that meet the necessary physical properties for high quality design.

This vehicle embodies a new paradigm of beauty and sustainability, challenging the cycle of disposability in product design. By emphasizing longevity, it promotes a mindful and harmonious relationship between humans and the environment.

Foams are often manufactured from petroleum-based materials, which are cost effective and simple to produce. However, Marlon's research into alternative materials led to the finding of plant based foams. To guarantee that the selected material meets industry standards, various tests were conducted with input from manufacturers.

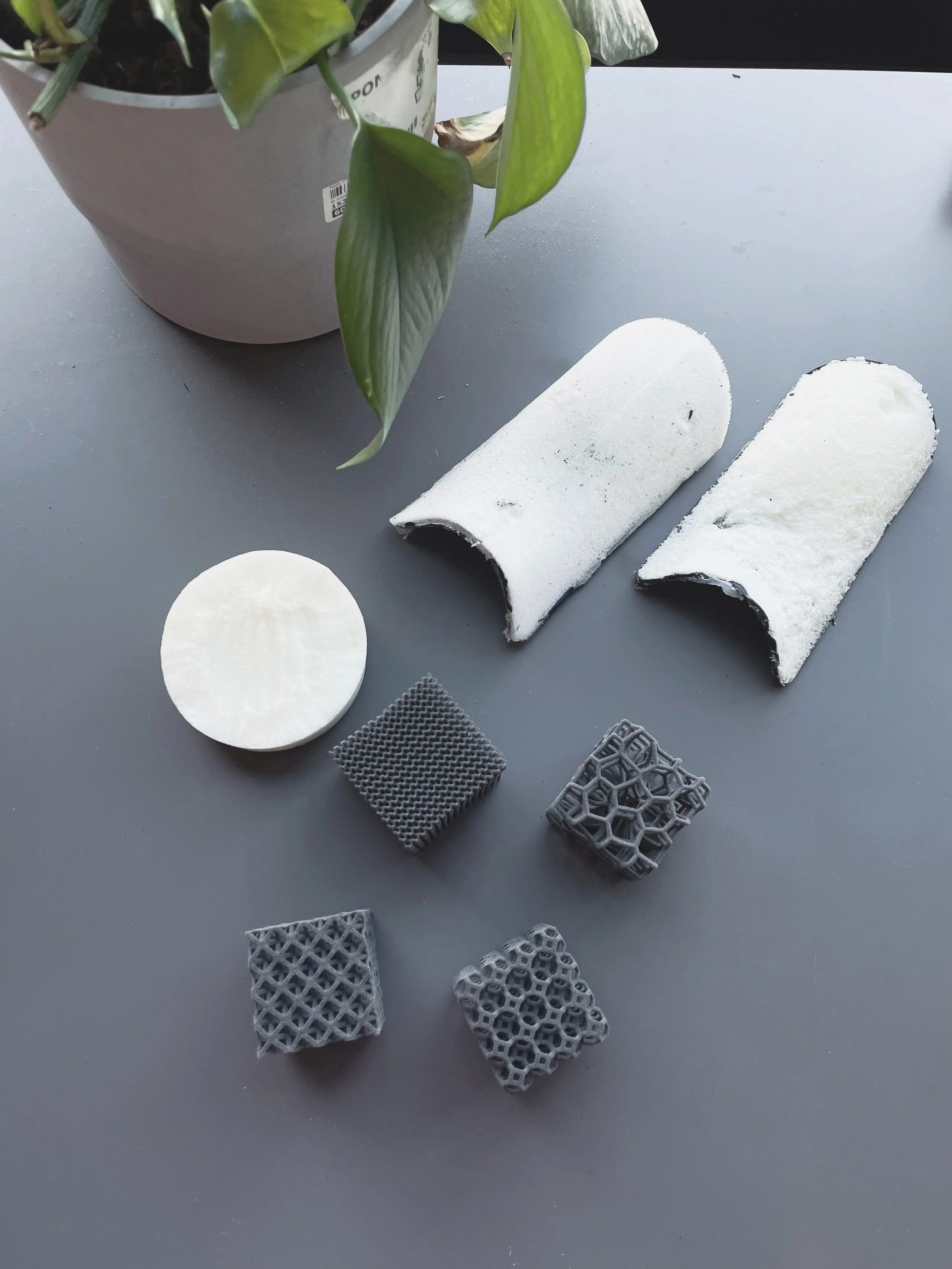

As alternative composites have evolved, Tarform has developed a proprietary bio-based composite. To diversify the alternatives for the best sustainable composite, Marlon sourced different composites that possess similar properties (even properties closer to carbon fiber) to Tarform's bio-based composite technology.

In research and development, 3D printing technology was useful for determining the appropriate shapes and mechanics for the vehicle's body and internal components. As the number of vehicle production increased, a more cost-efficient approach was necessary. While vacuum casting components are challenging to manufacture with bio-resins, Marlon's leadership in researching and building relationships with alternative suppliers has shown promising results.

*Skills: Material research Prototyping VRM Experimentation Communication / Collaboration / Critical thinking

KEY DESIGN

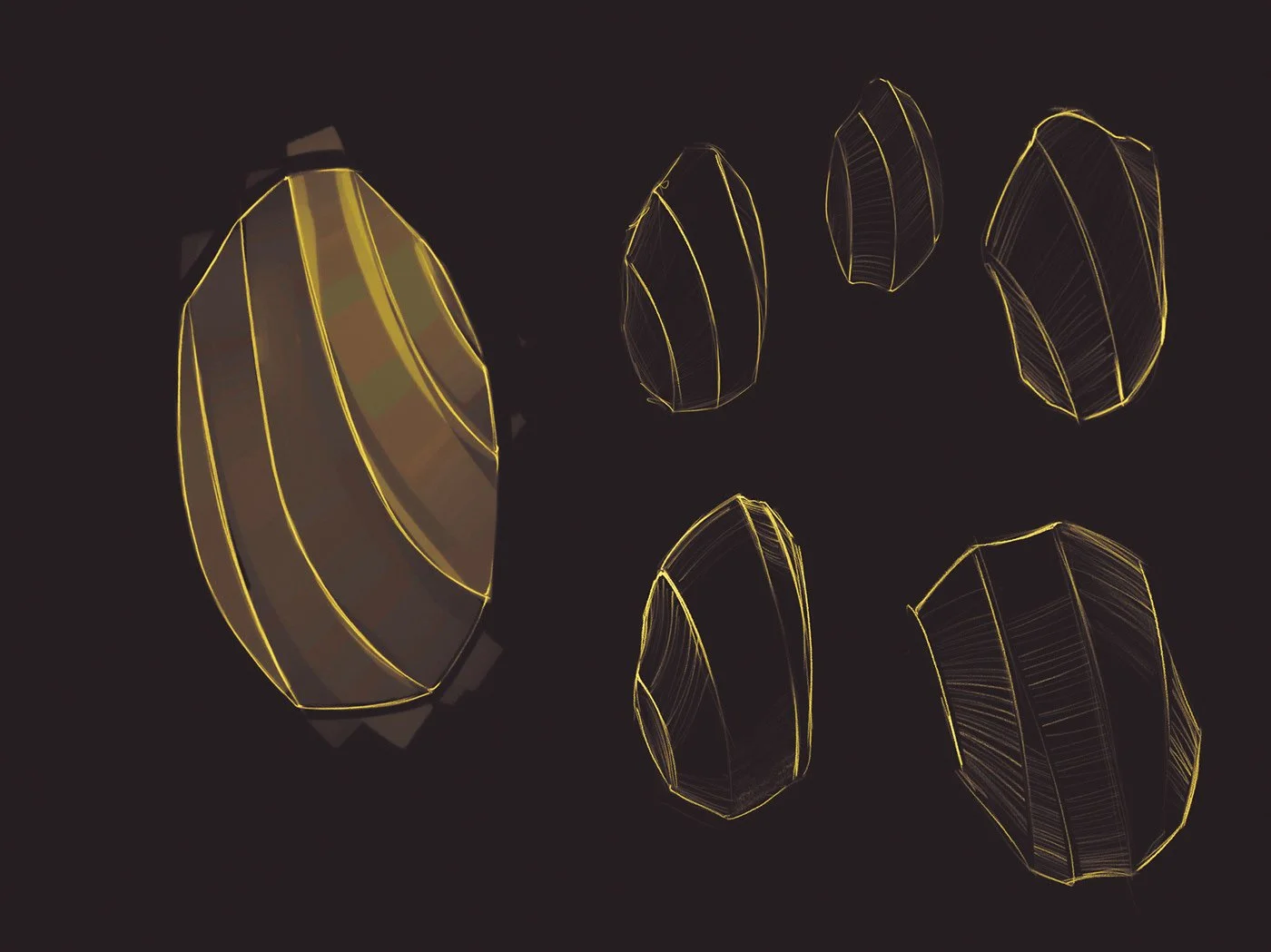

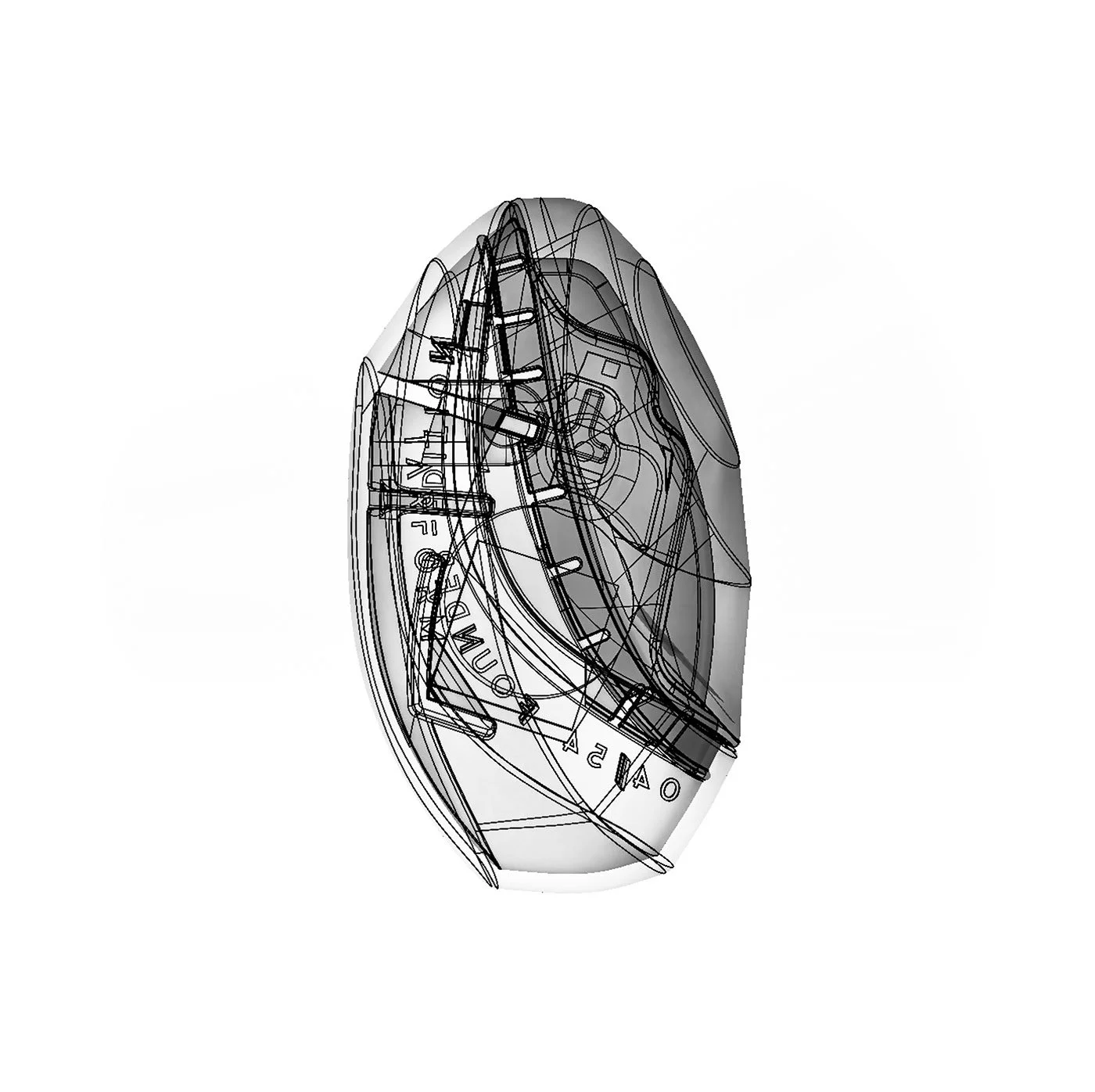

Taking inspiration from nature's ancient fossils, the design of the motorcycle key fob was shaped using biomimicry. Several hand-drawn sketches helped to find the proportions that would fit comfortably in a human hand, considering user experience as a crucial factor

The project utilized biomaterials and advanced technologies to achieve a metal 3D printed jewel as the key fob. A significant challenge was ensuring that the fob emitted the necessary radio signals to communicate with the bike. However, through the combination of different materials, a brass body was successfully implemented.

*Skills: Sketching Rendering 3D modeling Biomimicry Creativiy / Collaboration

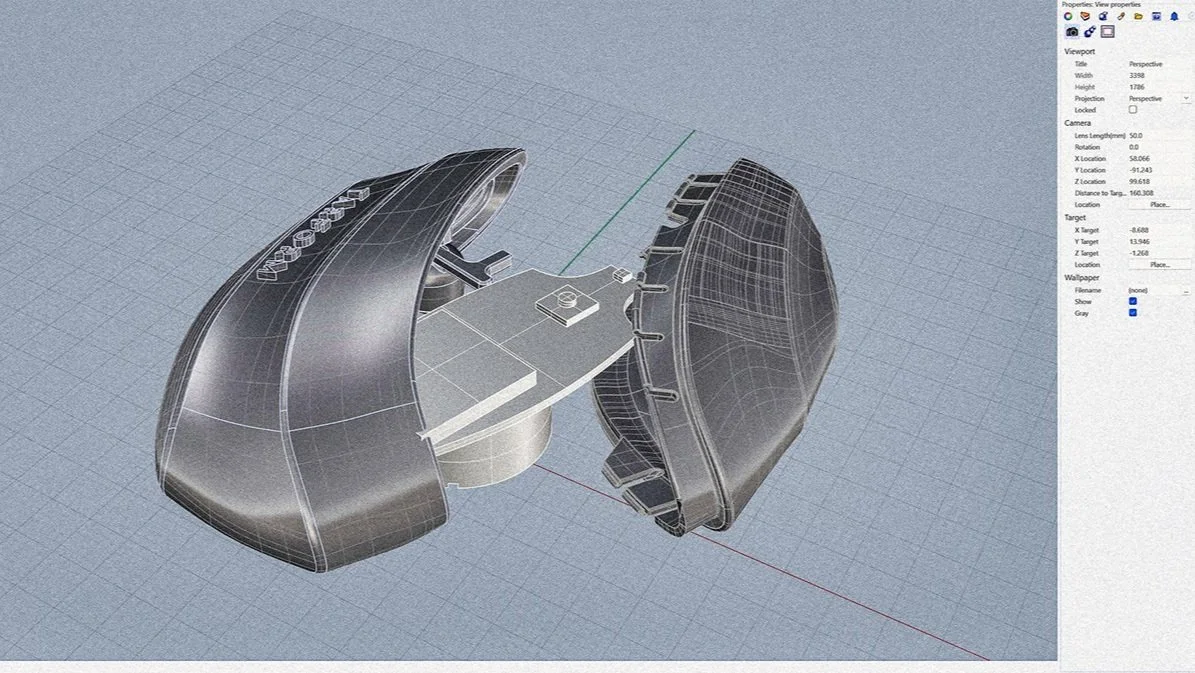

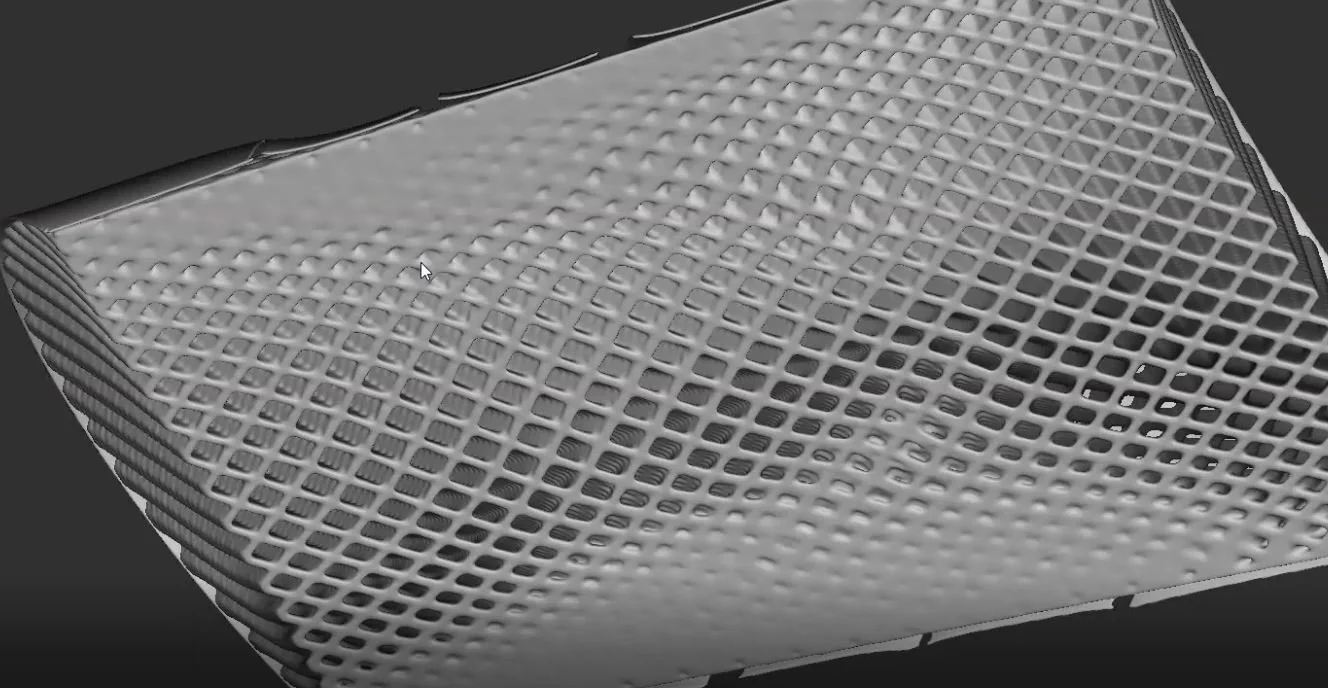

TOPOLOGY

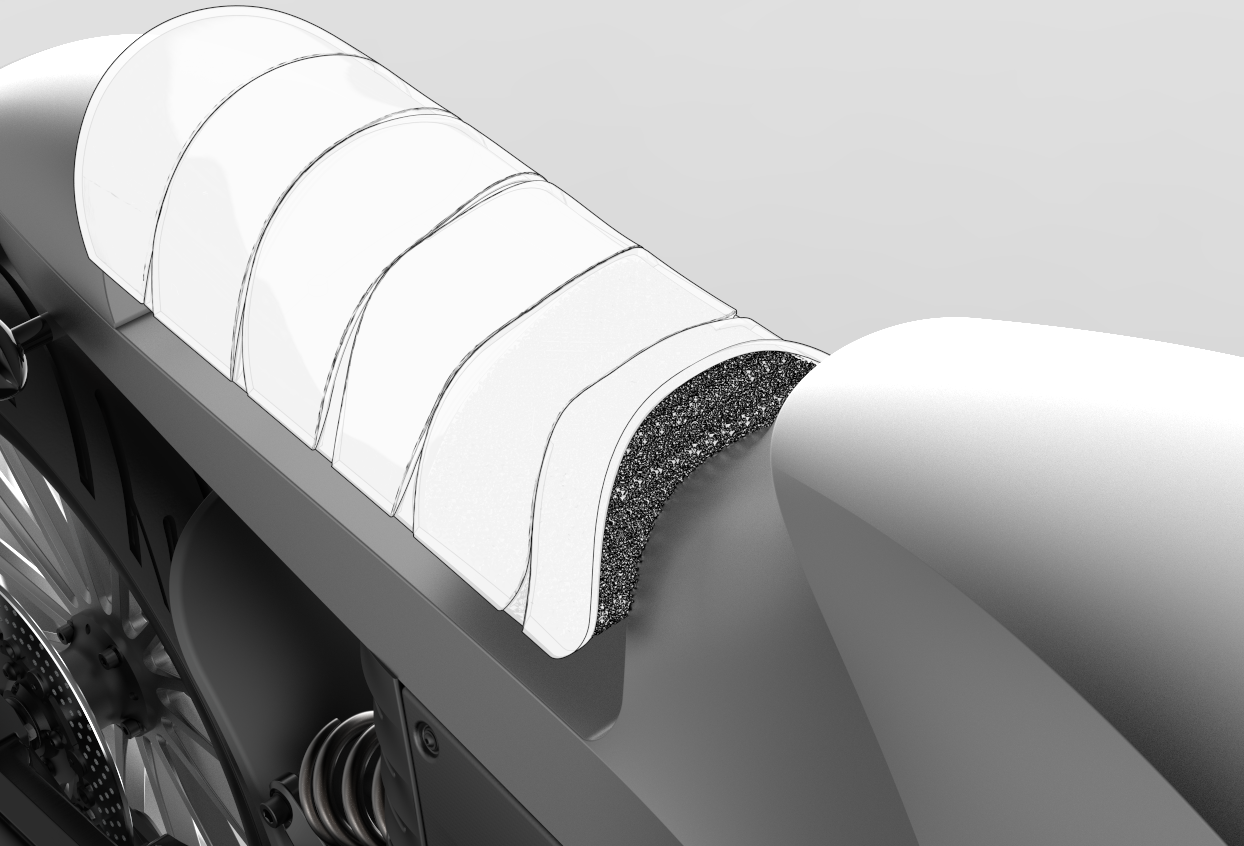

Topology optimization was utilized to achieve the best design iteration. On the other hand, multiple prototypes were studied alongside the project to develop the current design for the production bikes. The project is waiting for technology to catch up with imagination.

1

Scale prototype molding test

2

Scale prototypes of foam geometry

Marlon led the collaboration between Tarform, formlabs, and nTopology to design a topology-optimized motorcycle seat. The team tackled the challenge of utilizing Formlabs' proprietary materials with nTopology's software to optimize rider comfort. In-depth studies of weight distribution and material displacement informed the team on where to add or remove material, resulting in a seat design that perfectly balances both form and function.

3

4

*Skills: 3D modeling Hand prototyping Experimentation Design direction Creativiy / Critical thinking / Communication / Collaboration

Composite prototype

1:1 prototype

exhibition design

Marlon was tasked with designing a space for the New York Design Week that would create an atmosphere in line with the essence of the motorcycles, through the manipulation of light and space.

*Skills: Space design Organizational skills VRM Creativiy / Collaboration / Communication

Images courtesy of Dave Pinter.